With the recent COVID-19 crisis, supply chains across the globe have taken a huge hit. Lockdowns all around the globe as well as the impact on the shipping and logistics industry have created shortages of raw materials in almost every industry. And this has created an increasing interest in smart supply chain management solutions involving industry 4.0,

Almost 72% of respondents to a survey by EY on the impact reported a negative effect on their supply chain by the pandemic and 57% reported disruptions. In the same survey, only 2% of the respondents said they were prepared for the pandemic. Issues in the shipping and logistics sectors forced many companies to delay their product launches. Considering these problems, it’s no surprise that companies are investing in making their supply chains more robust and resilient.

It’s no surprise that smart supply chain solutions are getting a boost. Let’s explore what a smart supply chain is, how it works, and its benefits.

What is a smart supply chain?

Traditional supply chains are highly opaque and are constantly plagued by bottlenecks and delays. Unexpected delays are expected in every stage from shipping the raw materials to delivering the finished goods to retail stores. And it’s not easy for customers or clients to know the status of their shipment as well as the status of their products.

For example, goods like food products and pharmaceuticals have to be maintained in specific conditions such as within a temperature range and within certain levels of humidity. And in traditional supply chain networks, we have had the technology to maintain these conditions throughout. But we couldn’t monitor if these goods ever went out of this envelope.

Inventory management is also complicated with a traditional supply chain. While supply chain and inventory management software has made this a lot simpler, the process is still mostly manual and as with transit, it’s not easy to monitor the condition of goods in storage.

Smart supply chains are not just about shipping and logistics alone

Besides transit and storage, other stages in a supply chain, such as manufacturing and production, fleet management, deliveries, managing product returns, and others all face challenges in traditional supply chain management. For example, machinery can fail, factories can have unscheduled downtime; traditional supply chains are incredibly tricky, with many points of failure.

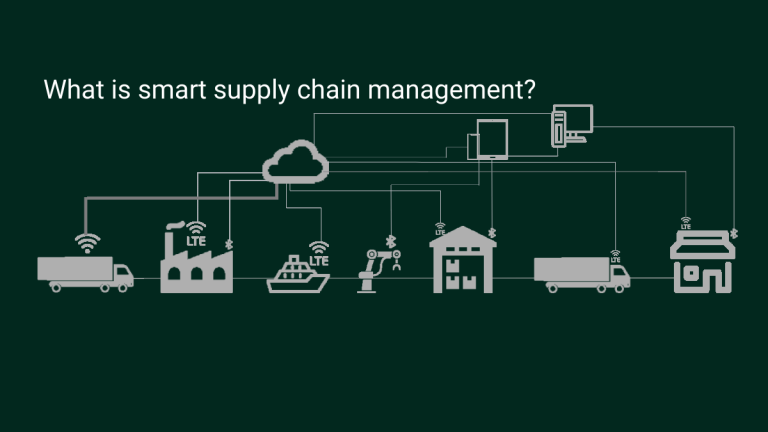

A smart supply chain attempts to bring visibility and transparency to the supply chain and make it more robust with the internet of things, AI, automation, and advanced analytics.

Merchants, retailers, and manufacturers can view the status and location of their products in real-time using IoT sensors. They can get better insights into the delivery and shipment times and better predict and avoid delays. These solutions will ensure appropriate conditions throughout transport and shipment. And with AI, they can improve quality management at every stage, leverage automation for faster and efficient manufacturing, and reduce and prevent bottlenecks at any stage of production.

What are the features of a smart supply chain?

Compared to traditional supply chain solutions, a smart supply chain presents a lot of features. Here are a few of them:

Smart supply chains let you track the location and condition of goods in real-time

With GPS systems, its possible for stakeholders to track the location of shipments in real-time. Even within warehouses and factories, you can use RFID, NFC, and other IoT sensors to keep track of raw materials and finished goods. In different stages of manufacturing or shipping, stakeholders can add additional information into these tags to keep track of the progress of each element through the supply chain.

Predictive maintenance and real-time monitoring of manufacturing facilities

Smart supply chains use sensor data from manufacturing and product handling equipment to understand their condition and schedule maintenance. Modern AI systems can predict when these machines may need maintenance by analyzing vibration, sound, and other data from them. This can reduce the need for unnecessary maintenance but also at the same time prevent unscheduled costly breakdowns.

Advanced fleet management

They’re both a feature and a component of a smart supply chain. These solutions track the locations of the delivery vehicles. Advanced solutions also keep track of the conditions of the vehicle and monitor the drivers to prevent accidents or delays. These solutions allow insights into the delays and inefficiencies in the individual routes and vehicles; for example, vehicles passing through a certain region at night may be using less fuel than the vehicles in the morning. With this information, fleet managers can optimize better fuel efficiency and delivery times throughout their fleet.

Smart supply chains feature a lot of automated processes

Smart supply chains leverage a large degree of automation in every stage. They may use automated quality checks when collecting raw materials. Robots may work alongside humans during the assembly process, and companies may automate large portions of the manufacturing process.

Many factories use robots and automation for final quality checks before shipping and with the advent of self-driving technology, we can expect automation even in the shipping industry.

Automation brings a lot of benefits to the stakeholders in a supply chain. It improves reliability in processes, results in consistent quality throughout, tends to be faster, and saves cost in the long run.

Smart warehouses and inventory management systems in smart supply chains

Smart warehouses use a combination of IoT, AI, machine vision, and robotics to streamline the management of goods. These technologies provide transparency into the warehouse, keeping track of the various goods and their quantity, their expiry dates, their storage conditions, and managing the warehouse most efficiently.

Advanced analytics to predict and prevent bottlenecks and delays

This is probably what makes smart supply chains worth it: the data and insights you can get from them. Using advanced big data analytics, smart supply chain solutions can make sense of troves of sensor data from machines, vehicles, storage units, and more and help companies make their supply networks more efficient and robust.

Supply chains require multiple industries to perform a synchronized dance. Smart supply chains make them more efficient with AI and IoT.