The Challenge

Seasonal demand swings of 400% between July and December. Supply chain disruptions when injection molding equipment failed during peak production

Manual forecasting for 180 seasonal stock keeping units (SKUs) taking 45 hours weekly. Forecast accuracy only 42% for items like space heaters and patio heaters

Legacy ERP couldn't handle seasonal complexity. No artificial intelligence in manufacturing capabilities for multi-product forecasting

$2.3M annual inventory costs from seasonal overstock. Post-Christmas markdowns reaching 60% on holiday décor items

23% stockout rate during Q4 peak season. Lost $1.8M in sales when a major client cancelled orders

Our Solution

Developed predictive analytics engine processing weather forecasts. Retail promotion schedules and injection molding cycle data included

Created automated supply chain & inventory optimization system. Real-time safety stock calculations for 180+ seasonal products

Implemented intelligent procurement system with supplier integration. Predictive maintenance scheduling for 12 injection molding machines

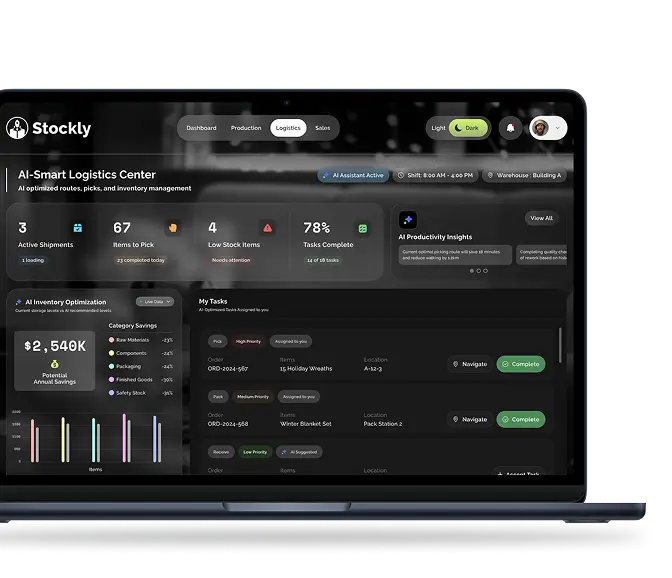

Deployed real-time dashboard showing seasonal trends. AI-powered robotics integration for automated packaging lines

Built custom AI in manufacturing platform. Machine learning algorithms analyze 3 years of seasonal sales data

AI Implementation Highlights

Advanced artificial intelligence in manufacturing deployment with intelligent automation and data-driven prediction.

Business Impact

Results that Matter

-

Reduced Inventory Costs by 37%

Supply chain & inventory optimization eliminated $850K in post-holiday markdowns. Artificial intelligence in manufacturing optimized seasonal planning

-

Improved Forecast Accuracy to 89%

AI in manufacturing models predicted Q4 demand within 8% variance. Predictive maintenance prevented 3 major equipment failures

-

Decreased Stockouts by 71%

Intelligent workflow automation maintained stock during Black Friday weekend. Predictive analytics prevented $1.2M in lost sales

-

Automated 82% of Procurement Decisions

AI-powered recommendations reduced manual planning from 45 to 8 hours weekly. Predictive maintenance optimized production schedules

-

Increased Profit Margins by 22%

Eliminated emergency freight costs of $180K annually. Optimized supply chain & inventory optimization improved cash flow

-

Enhanced Production Uptime by 28%

Predictive maintenance prevented injection molding downtime during December peak. AI-powered robotics monitoring reduced equipment failures by 65%

Why Nuventure

Top AI Service Provider in USA

Leading artificial intelligence in manufacturing company. 15+ successful supply chain & inventory optimization implementations

Best AI in Manufacturing Excellence

Proven ROI averaging 280% within 18 months. Workflow automation and predictive maintenance expertise for consumer goods

Industry-Specific AI Solutions

Deep understanding of seasonal manufacturing challenges. AI-powered robotics integration for packaging and quality control

Comprehensive Remote Monitoring Service

24/7 support during peak seasons with 99.8% uptime guarantee. Predictive maintenance effectiveness through advanced workflow automation

Cost-Effective AI Innovation

Enterprise-grade artificial intelligence in manufacturing solutions.

Great Ideas Deserve the Right Team!

At Nuventure’s AI Innovation Lab, we collaborate with you - securely and professionally - to turn your vision into reality. Let’s talk!